There are two main types of lasers: pulsed lasers and continuous wave (CW - Continuous Wave) lasers. Although both types of lasers produce light, they differ in the way it is produced and emitted. In this article, we explain the main advantages compared to CW lasers.

A continuous wave (CW) laser produces a continuous stream of laser beam. They are characterized by constant output power. CW lasers are used in applications that require a stable and uniform light output to melt surfaces, such as laser welding and laser cutting machines.

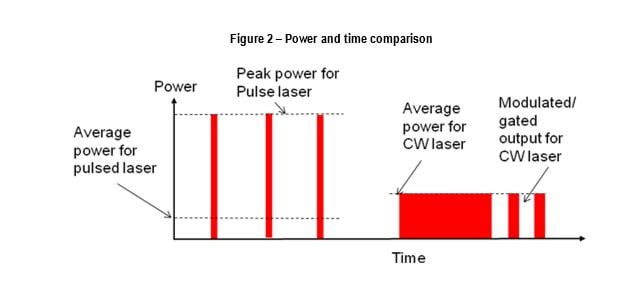

A pulsed laser produces bursts of laser light instead of a continuous stream. They are characterized by a pulsating power output that provides very high peak power at a relatively low average power. This type of laser is used when high peak power is required, e.g. for the removal of contaminants, minimal heated material area (HAZ - Heat Affected Zone) at once. For example, for laser cleaning.

Advantages of a pulsed laser:

An important difference with CW lasers is the price. CW lasers are generally cheaper (€/watt). Why? First, they do not require specialized components such as pulse-shaping electronics and optics that can withstand high peak power. In addition, pulsed lasers have many advantages:

- Higher peak power: Pulsed lasers can provide much higher peak power than CW lasers because they emit bursts of power over a short period of time. Pulsed lasers concentrate so much energy into nanosecond pulses that an ablative shock wave is created upon first exposure to a contaminant, making it an ideal treatment and cleaning method.

- Higher efficiency: Pulsed lasers are generally more efficient than CW lasers because they emit energy only when they are actively pulsing and because the ablative process requires high peak power. Without ablation, there is only evaporation, which takes longer and requires a higher average power. For many applications, such as paint removal, a 200W pulsed laser can easily outperform a 1kW CW laser by a factor of 4, while consuming only a fraction of the power and leaving the surface much cooler.

- Field of use: Where pulsed lasers really excel compared to CW lasers is the high variability in materials that come off without much effort. Thick marine paints, product fumes, adhesives, chemical compounds, rubber, rust… all of the above can be cleaned with pulsed lasers, where CW is limited to removing fresh local rust or oil.

- "Technical” material processing: Pulsed lasers can process materials in ways that CW lasers cannot. They emit a high energy pulse that creates a plasma, enabling more efficient and precise material processing. Want to clean or process stainless steel, aluminum, machine steel or copper wire without damage? Impulse lasers are ideal for this.

- Reduced heated area effect: Pulsed lasers can reduce the heated zone (HAZ) in materials because a high energy pulse is delivered in a short time, minimizing the amount of heat transferred to the material. Microfouling of the substrate can thus be avoided, even if the same surface is treated repeatedly. This can be useful in applications where it is important to avoid surface structural changes, such as in the injection molding industry or medical applications.

All in all, maybe the price of a pulsed laser is a higher investment, but the ROI is much higher. Especially if you choose a mobile or stationary laser device.

Source: https://www.linkedin.com/pulse/difference-between-cw-pulsed-laser-hardy-liu

Pulsed laser vs standing wave average and peak power