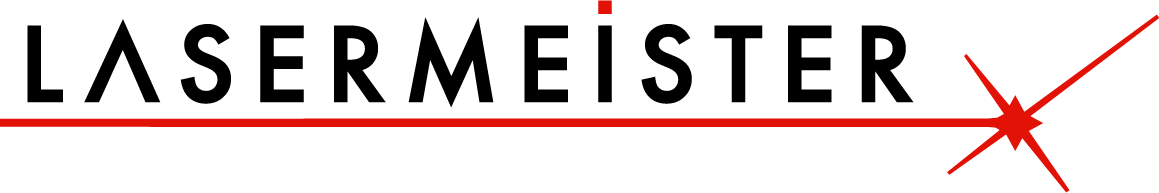

Fiber laser (fiber laser) workstation LMP9001300 PIRANHA FIBER is designed for high-quality and stable sheet metal cutting. Fiber lasers have almost 4 times longer lifespan and 2 times cheaper compared to equally powerful CO2 systems. The lower wavelength penetrates metals faster and does not require the addition of oxygen for cutting. The cutting edge stays clean and straight and often does not require any post-processing, unlike CO2 lasers, plasma machines and dies. Fiber laser the cost of use is lower compared to all other alternatives. The life of the laser resonator is approx. 50h. A laser machine with a power of 000W can cut 1000mm stainless steel at a speed of 2mm / min. If necessary, analog benches can be configured with powers up to 1000kW.

The work area of 1300x900mm also allows the use of longer sheet metal for cutting, thanks to the design that opens from behind. Coatings around the work area ensure maximum safety for the operator and protect against the spread of radiation to the surrounding environment. The device is built of industrial quality components and has a high assembly quality. Laser master equipment meets European safety and quality standards!

- 2 YEAR WARRANTY *

- Separate controller colored display

- Wireless control panel

- Compact design <3m2 of floor space

- Built-in control computer

- High operational safety due to closed cutting chamber

- Durable and practical Swiss design

- Best-in-class accuracy and speed up to 60mm / min

- 1300x900 mm working area

- Hatch for cutting longer material

- The possibility of using auxiliary gases at the laser head helps to cut more demanding metals

- FREE 1. regular maintenance!

- Cooling water flow alarm and fire alarm

- The set includes separate industrial cooling and plenty of useful accessories

Field of application |

|

Many different materials can be cut with this machine. Fiber lasers cut: Various steel alloys, stainless metal, aluminum, copper and many other materials. Fiber lasers are also used in industry, for example, for fast and uniform cutting of abrasives and many other organic materials. |

Laser technical information |

|

| Laser power | 1000w |

| Workspace | 1300x900mm |

| Engines | Schneider, France |

| Axle system | HiWin, Taiwan |

| Volume sensors | Omron, Japan |

| Focusing | Automatic and manual |

| Laser accuracy | ± 0,04 mm |

| Maximum laser speed | 60 mm / min |

| Min laser beam thickness | 0,07mm |

| Workflow | 240V |

| Bench dimensions | 1800x1500x1900 |

| Laser bench weight | approx. 850 kg |

Basic equipment |

|

| Our base price includes everything you need to start lasering! | |

| Cooling system | CW6.0A industrial refrigeration |

| Ventilation system | Integrated |

| Dashboard | comb desk |

| Software | RDWorks |

| Training | Basic training |

| Tools and equipment | USB and power cables |

| Safety | Heat sensor, 2 pairs of goggles |

| Extras | Optics cleaning kit, control panel, control computer, operating instructions, cutting head spare parts |

Possible additional configurations |

|

| Power up to 4kW; different work area sizes; material-specific desks; rotary axes; smoke filters; central compressed air interface; work indicator; etc. |

WARRANTY |

|

LASER BENCH 2 YEAR * |

The 2-year warranty also includes 1 free maintenance that can be used at the right time, but definitely for one year. All maintenance is performed on the basis of the maintenance book. To ensure reliability in production, it is recommended to maintain laser machines at least twice a year! |

ADDITIONAL WARRANTY * |

We offer all benches the opportunity to purchase an additional 1-year warranty, which includes 2 regular maintenance and an extended warranty for the device. All maintenance is performed on the basis of the maintenance book. |

* The warranty does not extend to the laser tube or software.

The assembly of laser machines is based on an order. Delivery time may depend on the bench configuration. Delivery time starts after payment is received. Upon arrival of the goods, we will deliver the bench, set it up and teach you how to use it. Some benches and spare parts are available on site.