The laser master is the official representative of the Bodor laser in Estonia. Bodor is the world's largest producer of fiber lasers. The equipment is high quality and modern. The Bodor Laser Development Center is located in Switzerland and the 30 m000 factory is located in China. Bodor fiber machines are used by tens of thousands of factories around the world. All production complies with CE // ISO2 / SGS standards.

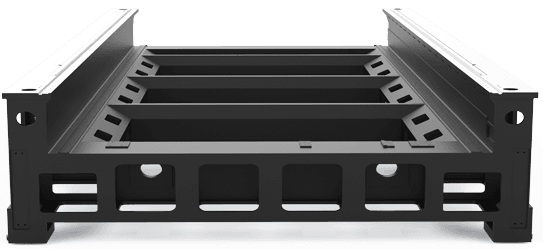

Cast iron body construction

One-piece molded baseboards ensure excellent rigidity and the highest accuracy. There is no deformation throughout the cycle.

Delta-shaped axle profile

The high-grade aluminum alloy structure is stable and secured against torsion and overturning, and has exemplary mechanical properties. This design of the axles allows efficient separation of internal and external loads.

German Beckhoff system

Openness

Support for non-standard solutions. Beckhoff can customize the interface and special features of the Bodor machine to support multi-touch screens and remotely monitor the processing status of the machine.

High performance

EtherCat bus control ensures fast signaling and high synchronization accuracy, especially for fast cutting.

Automatic nozzle change

The use of a rich and precise control system allows the automatic replacement of nozzles of different materials and thicknesses, cleverly saving the time of manual change, improving the efficiency of processing and making the whole process convenient; The latest automatic calibration and cleaning features allow you to perform fully automatic laser head calibration and nozzle cleaning, reducing repetitive manual work; The precision drive system ensures reliable accuracy and shift stability, so any replacement can be completely safe. The protection of the entire part in the form of a completely closed structure increases the work safety of the part and the safety of people.

Benefits of cutting

Rapid oxygen cutting of carbon steel (COF)

Thick sheet cutting is done at double speed and at the same time high quality cutting is ensured.

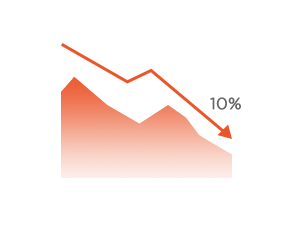

Economical fast cutting of carbon steel (CEF)

At a certain capacity, the cost of cutting is only 10% of the cost of cutting nitrogen. This allows you to create more economic value for your customers

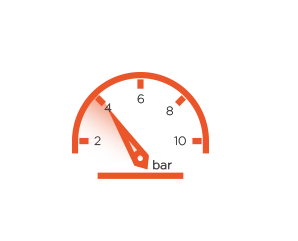

Fast Low Pressure Nitrogen Cutting (LNF)

When cutting 10 mm thick stainless steel, the nitrogen pressure is reduced to 4 bar.

Implement fast and accurate cutting

With an advanced CNC system to get control over the smallest details

Automated obstacle avoidance process

-

Intelligent collision protection

The 360 ° radar system prevents and detects all obstacles, allowing you to avoid obstacles immediately in the event of a rapid Z-axis collision.

-

Higher efficiency, lower costs

A lower laser head damage rate reduces customer maintenance costs and extends device life.

Intelligent perforation technology

A new generation of intelligent perforation technology significantly reduces the perforation time, the average perforation time of medium and thick leaves is reduced to 4 seconds.

This prevents the formation of stain holes and the occurrence of failures due to overheating of the stain during long-term perforation. Laser malfunction detection and intelligent alarm provide protection when laser beam anomalies occur and no material penetration occurs.

Equipment power: 2KW-20KW, IPG / MAX

Material: carbon steel, stainless steel, aluminum

Thickness: up to 50mm